Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

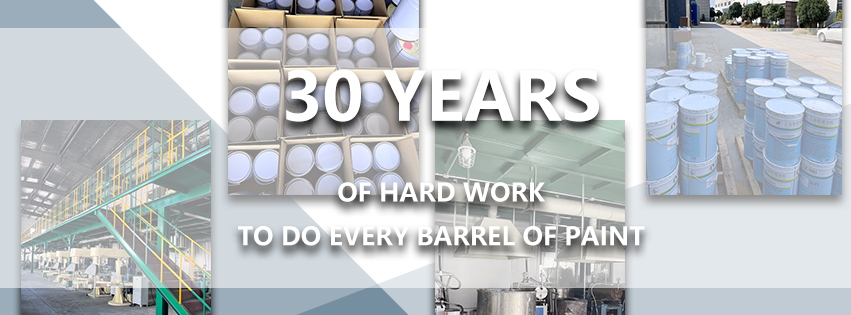

Steel structure is one of the main types of building structure, which is widely used in large factories, venues, super high-rise buildings, Bridges and other fields. But the steel structure is easy to rust, so the general steel structure to rust removal, galvanized or spraying coating. Steel structure coating is to prevent steel structure corrosion and corrosion.

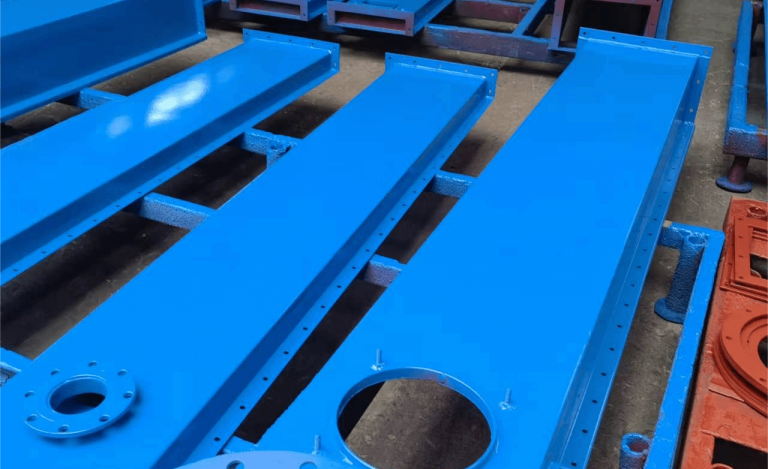

Such as epoxy zinc rich primer, rust prevention, alkali resistance, oil resistance and other functions, and a variety of surface coating combined with use;

Intermediate paint can fill the gap between the primer and the finish, improving the protection of the coating. Such as epoxy cloud iron intermediate paint, has good rust resistance, weather resistance, water resistance and chemical resistance.

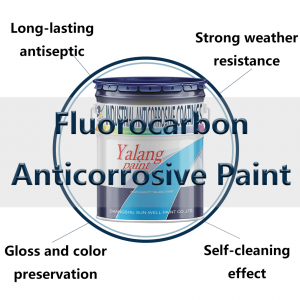

Such as fluorocarbon topcoat and acrylic amino polyurethane topcoat, with good corrosion resistance, weather resistance, ultraviolet resistance, effectively protect the primer from the external environment;

Rust resistance, weather resistance, water resistance, chemical resistance and other factors.

Use the environment and use requirements, select the suitable coating variety and coating scheme. For example, for steel structures in the Marine environment, it is necessary to choose coatings with good salt spray resistance; for industrial steel structures with industrial air pollution resistance.

Alkyd antirust primer + alkyd topcoat

Epoxy zinc-rich primer + epoxy cloud iron intermediate paint + epoxy topcoat

Epoxy zinc-rich primer + epoxy cloud iron intermediate paint + polyurethane acrylic finish paint

Epoxy zinc-rich primer + epoxy cloud iron intermediate paint + aliphatic polyurethane finish

Epoxy zinc-rich primer + epoxy cloud iron intermediate paint + fluorocarbon finish paint

Before the implementation of rust removal, cleaning and loosening of the paint layer, it is necessary to use the cleaning agent to remove the surface oil, iron oxide and other substances. At the same time, the cleaned surface also needs to be kept clean and dry.

For wear and corrosion of steel members need a large degree of rust removal or replacement of weak parts of the members. These works require the use of suitable cutting and welding tools to ensure a good quality of work and operational safety.

Primer paint brush, generally can use spraying or brush paint, primer can be red Dan antirust paint, epoxy zinc rich primer, paint should be stirred evenly, control the adhesion of the paint. Use spraying to move evenly, try not to stop in the middle, in case the thickness of the paint is different, for the number of coating channels should be combined with the actual demand.

After the primer is completely dry can spray intermediate paint, generally 12 hours, construction process and primer similar, general brush can be.

After the middle paint spraying surface paint, paint mixing evenly, according to the amount of materials configuration, can not configure too much, whether the middle paint, or top paint should ensure that the front paint is completely dry, before carrying out the painting work of the next anti-corrosion paint.

1 After coating the steel components, they should be temporarily enclosed and isolated to prevent stepping and damage to the coating.

02 After coating the steel members, in case of strong wind or rain within 24 hours, they should be covered to prevent being contaminated with dust or water vapor and avoid affecting the adhesion of the coating.

03 Steel members after coating should pay attention to prevent collision, prevent coating damage.

Before coating, cover other semi-finished products to prevent pollution.

Maintenance and repair of fire retardant coating coating. In case of violent vibration, mechanical collision or rainstorm, the coating should be damaged, and timely repair the damaged parts or take other treatment measures.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.