Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

With the maturity of production technology and the accelerated development of application products, its characteristics and advantages gradually appear, and it has entered the planning period of large-scale production and application in the market development experiment. It is expected that in the next three years, China’s water-based epoxy will enter an explosive growth period, which will bring huge impact and change to the existing epoxy resin application market and potential application market in China. It can not only replace the use of solvent epoxy, but also the contribution of environmental protection and safety cannot be underestimated.

Waterborne epoxy floor coating has the same performance as the solvent type epoxy floor coating, not affected by the weather changes, and can be made into corrosion resistant, elastic, anti-static functional floor, suitable for modern industrial needs of the ground. The existing water-based epoxy floor coating can be applied in the pharmaceutical, food, hospital, textile, chemical, electronics and other industries, office buildings, warehouses and laboratory floor coating, especially for the first floor, basement, underground parking lot and other relatively humid environment. As a green environmental protection product, the water-based epoxy floor floor is bound to be recognized and widely used by people.

1.High coating adhesion, corrosion resistance and chemical resistance, high hardness, good wear resistance and excellent electrical insulation;

2.With water as dispersion medium, small smell, non-combustible, and storage, transportation and use meet the requirements of environmental protection;

3.Some water in the coating after curing, which can avoid the coating defects of foaming, deformation, hollow and even peeling.

4. easy to use, good construction performance, construction tools can be directly cleaned with water to reduce the construction cost;

5.the scope of application, can be used in room temperature and humid environment, and the old substrate also has good recoating;

6.decorative, smooth surface, half light, matte and a variety of colors available.

Water epoxy without vibration anti-landslide road has durable, anti-skid and wear-resistant, tire protection, reduce tire noise, comfortable without vibration, rain self-cleaning and other excellent performance, and the pattern is beautiful and bright, strong guidance, eye-catching safety. It is very suitable for the entrance and exit ramp of underground garage with large slope and many curves. The construction technology of water-based epoxy non-vibration anti-skid rate path includes base surface treatment, bottom coating port transportation, repair, compressive layer construction, layout marking, anti-skid layer construction, cleaning beautiful grain paper, surface coating construction and maintenance.

Aqueous epoxy bottom protection has excellent adhesion, chemical resistance, good alkaline resistance, hard coating and other characteristics, suitable for containers, trains, ships, oil storage tanks and so on. The requirements of water-based epoxy anticorrosion are very different for different applications, so in addition to choosing a very high-quality epoxy resin and water-based epoxy anticorrosion, but also pay attention to the selection and collocation of functional anti-corrosion filler. By adding different fillers, it can be made into water epoxy zinc-rich bottom coating, water epoxy iron oxide red bottom coating, water epoxy zinc sulfate rust bottom coating, aqueous epoxy cloud iron coating, water epoxy anti-rot surface coating, etc. Water-based epoxy anti-corrosion in the coating process should be very attention to the bottom coating and coating environment humidity control, because the water epoxy anti-corrosion itself water, steel plate in the surface is easy to rust on the coating process, steel sandblasting coating as soon as possible after the first undercoating, the first undercoating as soon as possible, reduce the water stay time to reduce the possibility of corrosion, and choose the environmental humidity low time coating, avoid rain, fog in the morning time, and maintain good ventilation.

Due to water epoxy corrosion in aqueous epoxy resin and water poxy curing agent in order to do good water dispersion and contains hydrophilic substances, this is bound to reduce the water epoxy corrosion water resistance, so water epoxy corrosion resistance and salt resistance the two indexes is crucial, water epoxy corrosion resistant salt spray general requirements for more than 500 hours.

Waterborne epoxy adhesive in all kinds of resin is famous for its high bond strength, and metal, glass, cement, wood, plastic and other materials, especially the high surface activity material with strong adhesive relay (for small materials such as polyethylene road, polypropylene, gas, industry for small relay, must first surface activation treatment), for different processes and applications, have room temperature curing agent and heating curing, heating curing type of water-based epoxy tree and water epoxy curing agent mixing can be used for a long time, this assembly line production.

Waterborne epoxy joint king is a new type of adhesive connecting the cracks of objects, with strong crack resistance and adhesion force, strong wear resistance, good water resistance. Corrosion resistance, not color permeable, safety and environmental protection, and has superior accumulation performance, simple construction, thousand solid time moderate can quickly shape, room temperature 20-25℃ 2 hours dry, 24 hours, three days to reach the best hardness. High-density, high-strength mesh coating is formed at the joints after dry penetration.

Water epoxy cement mortar (concrete) additive is composed of water epoxy resin and water epoxy curing agent, which has good compatibility with cement mortar (concrete). Added to the mortar (concrete), through the water-based epoxy crosslinked curing and cement hydration formation with high performance of space mesh structure of organic-inorganic composite material system, enhance, impermeability and anti-chemical effect, can be in the wet interface and environment rapid curing, does not produce crack, adapted to water conservancy, underground civil air defense engineering, road and bridge building defects repair bonding, can also be seepage leakage material.

Water epoxy cement mortar (concrete) additive is composed of water epoxy resin and water epoxy curing agent, which has good compatibility with cement mortar (concrete). Added to the mortar (concrete), through the water-based epoxy crosslinked curing and cement hydration formation with high performance of space mesh structure of organic-inorganic composite material system, enhance, impermeability and anti-chemical effect, can be in the wet interface and environment rapid curing, does not produce crack, adapted to water conservancy, underground civil air defense engineering, road and bridge building defects repair bonding, can also be seepage leakage material.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

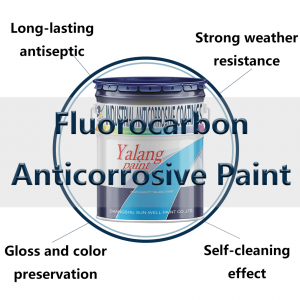

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.