Epoxy coal tar paint

Epoxy coal asphalt paint has excellent seawater resistance and durability, excellent anti-corrosion performance, good corrosion resistance to soil media, good adhesion, impact resistance and wear resistance.

EPOXY COAL TAR PAINT

PRODUCT PARAMETERS

| Appearance | black |

| Ratio | Part A : Part B = 20 :20 (weight ratio) or according to the ratio required by the customer |

| Dry film thickness | 100 μm |

| Theoretical dosage | 200g/m2 flash point 35 °C |

| Dry schedule dry | 2h (25 °C) Practical 24h (25 °C) |

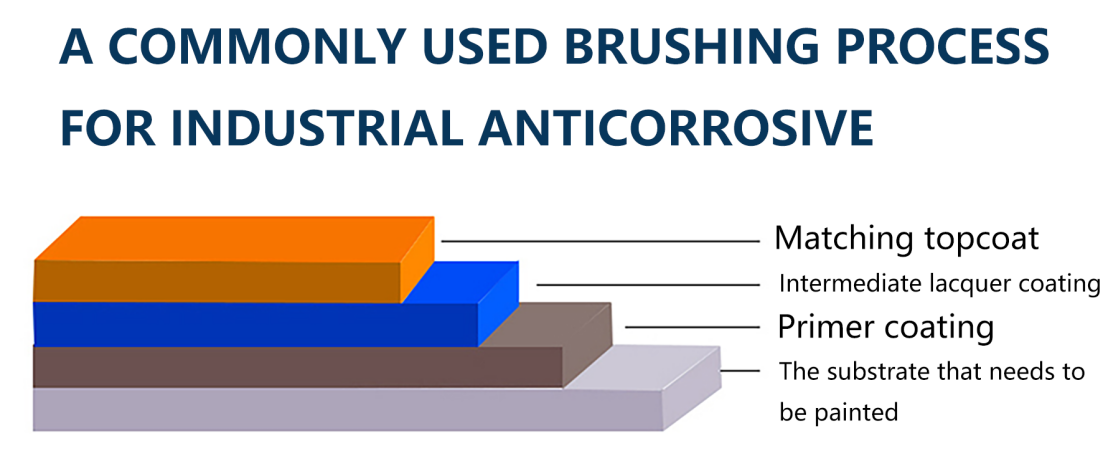

| Package recommendation | 1. 1 ordinary anticorrosive primer + 1 airless spray of topcoat, 3-5 coatings for brush coating or roller coating, and the thickness of the dry film is more than 200um. 2. Cover the anticorrosive layer with epoxy asphalt reinforced with glass fiber cloth, strengthen primer-topcoat, fiberglass cloth-topcoat-topcoat, and the thickness of the dry film is more than 400mm. (1 cloth and 4 oils) Extra reinforced primer – top coat fiberglass cloth – top coat fiberglass cloth – top coat – top coat, dry film thickness of more than 600mm. (2 cloth 5oil) |

| Surface treatment | Oxide scale steel: sandblasted to Sa2.5 grade. Non-scale steel: sandblasted to Sa2.5 or elastic grinding wheels to St3. Steel coated with shop primer: Sandblasted with a good sweep or sanded to St3 in the rust with elastic grinding wheels. Welding, flame cutting or pyrotechnic correction of burning parts: remove welding slag and spatter, polish and flatten, and grind to St3 level with elastic grinding wheels. The front coat should be completely dry. Remove all oil and debris from the paint film. |

PRODUCT DESCRIPTION

| Features | Epoxy coal tar pitch anticorrosiv primer is a two-component long-lasting anticorrosive coating composed of epoxy resin, coal coke asphalt, epoxy curing agent, anticorrosive pigment, physique pigment, additives and solvents. It is characterized by excellent seawater resistance and durability, excellent anti-corrosion performance, good corrosion resistance to soil media, good adhesion, impact resistance and wear resistance. |

| Construction conditions | The temperature of the substrate must be higher than 3 °C Relative humidity is not greater than 85 °C coating method Airless spraying thinner ; Matching thinner Dilution 0-5% (by weight of paint) Nozzle diameter 0.4-0.5mm Injection pressure : 20-30Mpa (about 200-250kg/cm2) Air spraying is not recommended for large-area construction, and is suitable for small-area repairs or small painted parts. Thinner : Matching thinner Dilution 0-10% (by weight of paint) Nozzle diameter 2.0-3.0mm Air pressure : 0.2-0.4Mpa(about 2-4kg/cm2) Roller/brush coating is mainly used for small area painting and refinishing. Diluent ; Matching thinner Dilution 0-3% (by weight of paint) |

| Precautions | Before coating, the paint should be mixed and stirred evenly according to the ratio, it can be used after half an hour of curing, it is now used, usually it is not necessary to add thinner in the coating, the viscosity of the paint is too high when the thinner must be added but not excessive, when the glass fiber cloth is coated with the coating, the glass fiber cloth should be tightened and smoothed, and each layer of paint must be sufficiently thick, the paint film is full, and no leakage occurs, and the mesh of the glass fiber cloth is required to be filled with the top coat, and the surface is smooth paint film, which is covered as required. |

| Storage and packaging | Part A 20L barrel 20KG Part B 20L barrel 20KG Shelf life : 12 months Part A 20L Drum 20Kg Shelf life : 12 months Part B 20L barrel 20KG Shelf life : 12 months |

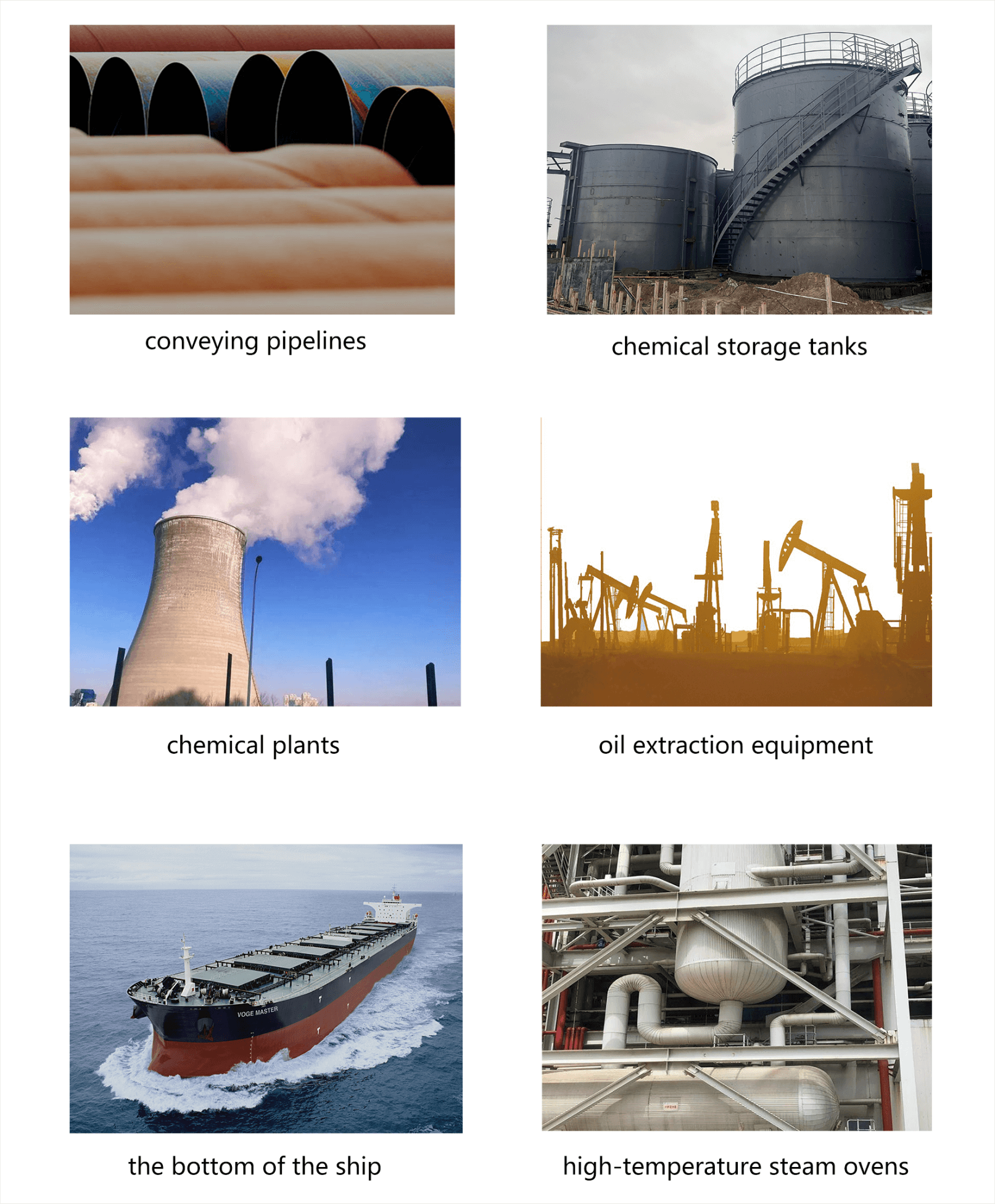

SCOPE OF APPLICATION

It is used for the anti-corrosion coating of oil and gas pipelines, tap water, gas, heating pipelines, power plants, cooling water buried pipelines of industrial and mining enterprises, chemical plants, sewage treatment plants, oil refineries and other buried pipelines and steel storage tanks, gas cabinets, and floors.