Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

Mechanical paint is a type of spray coating material that isa both familiar and unfamiliar. While many people might be aware that it is primarily used for industrial equipment coatings, they might not have a detailed understanding of it. Below is a brief introduction to the types and characteristics of mechanical paint, which may be helpful for those interested in this area.

Mechanical paint is a chemical mixture coating that firmly adheres to the surface of mechanical objects, serving purposes such as protection, decoration, marking, and other special uses. It falls under the category of organic polymer materials, and the coating film it forms is a type of polymer compound. According to modern classifications of chemical products, mechanical paint is considered a fine chemical product. Modern mechanical paints are gradually becoming multifunctional engineering materials and are an important sector in the chemical industry.

The characteristics of mechanical paint include being designed specifically for coating factory machinery and equipment, typically applying specialized processes and equipment for application and drying. The production characteristics of mechanical equipment include mass production, batch production, and continuous production. Therefore, mechanical paint products are usually produced in large quantities and require specialized application and drying technologies. The processes are often semi-automated, automated, and continuous, with large packaging, and sometimes even delivered by tankers.

Since mechanical paint is intended to protect and decorate industrial equipment surfaces, its performance must meet the requirements of industrial products. This means it needs to have coating rheological properties suitable for application and drying requirements, and once dried, it should have properties such as adhesion to the substrate, interlayer adhesion, appearance (color), durability, and hardness.

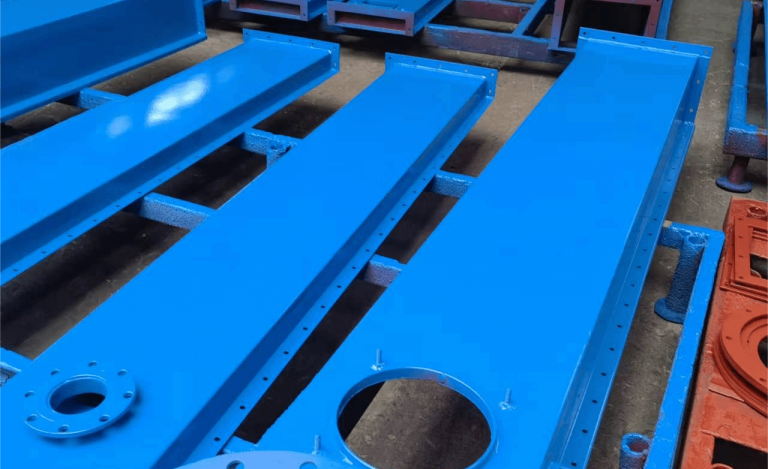

Industrial paint is a coating with a strong adhesion to inorganic materials like metals. It has excellent mechanical properties, wear resistance, and impact resistance. It is primarily used in hardware coating, automotive applications, and metal corrosion protection. Currently, many mechanical paints use industrial epoxy coatings.

This type of paint offers strong adhesion and advantages such as resistance to acids and alkalis, high strength, and long-lasting color stability. It performs well in various environmental conditions and is widely used in low temperatures or on other substrates, such as bridges, docks, and steel structures.

Metal paint features good leveling properties, fast drying, strong adhesion, wear resistance, and impact strength. It maintains a long-lasting bright appearance. It is used in a wide range of applications, including engineering machinery, large instruments, and doors and windows. Prior to application, surface preparation is required.

Main Uses: Coating for general metals, woodwork, home decoration, agricultural machinery, automobiles, buildings, etc.

Main Uses: Interior and exterior wall coating, leather coating, wood furniture coating, floor coating.

Main Uses:Automotive, furniture, electrical appliances, plastics, electronics, buildings, floor coating.

Main Uses:Automotive, furniture, electrical appliances, plastics, electronics, buildings, floor coating.

Main Uses:Automotive, wood furniture, decoration, metal corrosion protection, chemical corrosion protection, insulation coatings, instrument coatings.

Main Uses: Wood furniture, decoration, metal decoration.

Main Uses: Automotive, electrical appliances, instruments, wood furniture, metal protection.

Main Uses:Wood furniture, chemical corrosion protection, metal protection, flooring.

Main Uses: Insulation, metal corrosion protection, chemical corrosion protection, general decoration.

Main Uses:Chemical corrosion protection, metal protection, insulation, metal primers, exterior coatings.

1.By Coating Form: Powder, Liquid

2.By Film Formation Mechanism: Conversion Type, Non-Conversion Type

3.By Application Method:Brush, Roller, Spray, Dip, Pour, Electrophoresis

4.By Drying Method:Air Drying, Baking, Moisture Curing, Steam Curing, Radiation Curing)

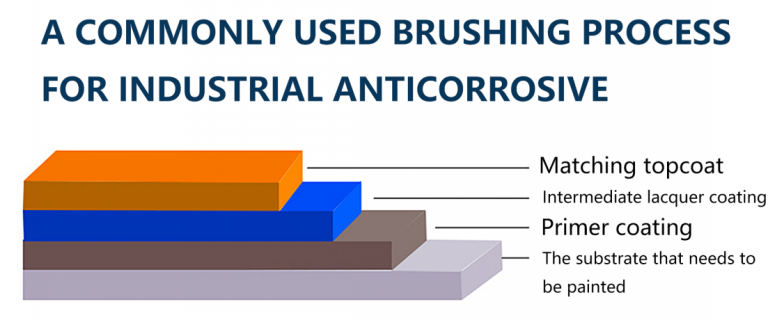

5.By Application Layer:Primer, Intermediate Coating, Topcoat, Filler, etc.

6.By Film Appearance:Clear, Colored; Gloss, Matte, Semi-Gloss, High Gloss; Hammered, Textured, etc.

7.By Application Object:Automotive Paint, Machinery Paint, Machine Tool Paint, Metal Paint, etc.) Marine paints can also be categorized based on usage and environmental conditions, such as anti-rust coatings, anti-corrosion coatings, anti-fouling coatings, weather-resistant coatings, heat-resistant coatings, and specific functional coatings like hull paint, deck paint, marking paint, and others.

8.By Film Performance:Anti-corrosion Paint, Insulation Paint, Conductive Paint, Heat-resistant Paint, etc.

9.By Film-forming Substances:Alkyd, Epoxy, Chlorinated Rubber, Acrylic, Polyurethane, Vinyl, etc.

Mechanical paint provides protection against corrosion, water, oil, chemicals, light, and temperature. Objects exposed to the atmosphere are subject to corrosion and degradation from oxygen and moisture. A coating forms a protective layer on the surface, preventing or delaying these destructive processes, thus extending the lifespan of various materials. Therefore, protection is a primary function of coatings.

Mechanical paint affects color, gloss, patterns, and smoothness. Painting mechanical objects can achieve vibrant, colorful appearances, enhancing the aesthetic quality of living environments and contributing significantly to both material and spiritual aspects of human life.

1.Oil: Includes drying oils and semi-drying oils, which are one of the main film-forming substances.

2.Resins: Includes natural and synthetic resins, which are also part of the main film-forming substances.

3.Pigments: Includes coloring pigments, body pigments, and anti-corrosive pigments, which are numerous and are secondary film-forming substances.

4.Thinners: Includes solvents and diluents used to dissolve the above substances and adjust viscosity, serving as auxiliary film-forming substances.

5.Additives:Includes drying agents, curing agents, plasticizers, and moisture-proof agents, which also belong to auxiliary film-forming substances.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.