Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

Application Method: Various methods are available, but spraying is optimal; avoid electrostatic and electrophoretic methods.

Compatible Paints: Can be used with single-component volatile paints. As a topcoat, it can be applied over epoxy, polyurethane, or olefin and rubber paints.

Application Tips: Stir thoroughly; use a mixed solvent of hydrocarbons and esters as a thinner. The film thickness is low, requiring multiple coats.

Application Method: Various methods are available, but spraying, brushing, and rolling are preferred; avoid electrostatic and electrophoretic spraying.

Compatible Paints: Can be used as a primer or topcoat. When used as a primer, various organic paints can be selected for the topcoat, but the primer should only be epoxy or the same type of paint.

Application Tips: For two-component paints, mix with a hardener evenly. The paint has a specific activation and usage period. High-pressure airless spraying can achieve thicker coatings.

Application Method: Various methods are available, but spraying is optimal; avoid electrostatic and electrophoretic methods.

Compatible Paints: Generally used alone; epoxy can be chosen as a primer, and alkyd or oil-based resin emulsion can be selected for the topcoat.

Application Tips: Control the drying temperature to be higher than the application temperature. Avoid rapid temperature increases during drying. For silicone insulating paint, prevent dust and foreign matter from mixing in, and do not mix with other resins. A drying agent can be added, and it should be used promptly.

Application Method: Various methods are available, but brushing, spraying, and rolling are preferred; avoid electrostatic and electrophoretic methods.

Compatible Paints: Can be used as a primer, with single-component volatile or alkyd paints as topcoats; primers should be epoxy, polyurethane, or other two-component paints.

Application Tips: Dries quickly at higher temperatures. Add high-boiling point and aromatic solvents for longer drying times. High-pressure airless spraying can achieve higher film thickness.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

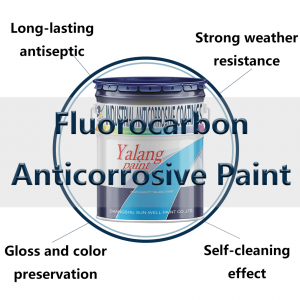

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.