Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

Abstract:Fluorocarbon paint and alkyd enamel are two distinct types of coatings, each with its own advantages and applicable scenarios. They differ in terms of composition, characteristics, and applications. Fluorocarbon paint is a high-performance coating known for its excellent weather resistance, corrosion resistance, pollution resistance, and UV protection. It is widely used in areas requiring high durability and corrosion resistance, such as building facades, metal structures, aluminum curtain walls, and automotive exteriors. Alkyd enamel, on the other hand, is a fast-drying, abrasion-resistant paint with good adhesion and gloss. It is commonly used for painting metal surfaces, wooden furniture, and flooring to enhance durability and aesthetics.

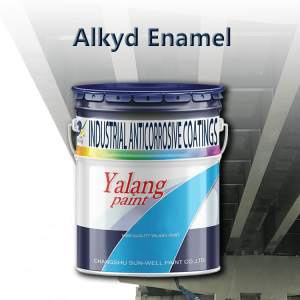

Fluorocarbon paint is a high-performance coating primarily composed of fluorinated resins, such as polyvinylidene fluoride (PVDF)resin. It offers superior weather resistance, chemical corrosion resistance, and high-temperature stability, making it suitable for outdoor and demanding environments.

Alkyd enamel is a type of paint known for its good adhesion and abrasion resistance, with the main component being alkyd resin. It is suitable for coating surfaces like metals and wood, forming a durable protective film.

Fluorocarbon paint excels in weather resistance, able to withstand UV rays, chemical corrosion, and high temperatures over long periods without fading or aging. It also has a low surface tension, making it easy to clean and resistant to dirt accumulation.

Alkyd enamel provides good adhesion and abrasion resistance, protecting surfaces from physical damage and scratches. However, its corrosion resistance is relatively lower, making it less suitable for extreme environments.

Fluorocarbon paint is widely used in building facades, metal structures, aluminum curtain walls, and automotive exteriors where high weather resistance and corrosion protection are required.

Alkyd enamel is often used for metal surfaces, wooden furniture, flooring, and similar applications to improve wear resistance and decorative appeal.

Fluorocarbon paint and alkyd enamel are different types of coatings with distinct characteristics and suitable applications. The choice between them should be based on specific needs and application environments.

Fluorocarbon paint, being a high-end coating, offers excellent weather resistance, corrosion resistance, pollution resistance, and UV protection. It effectively protects surfaces from environmental damage while maintaining good gloss and color stability. Fluorocarbon paint is typically used for high-end buildings, such as villas, office buildings, hotels, and infrastructure projects like highways and large bridges that require long-term durability and aesthetic appearance.

Alkyd enamel is a fast-drying, abrasion-resistant paint with good adhesion and gloss. It is suitable for both indoor and outdoor use with relatively short drying times. Alkyd enamel is commonly applied to metal and wooden surfaces, including furniture, doors, windows, railings, and steel structures.

In summary, the choice between fluorocarbon paint and alkyd enamel depends on the following factors:

1.Usage Environment

If the coated object needs to withstand harsh climate and environmental conditions over a long period, especially for outdoor structures, fluorocarbon paint may be more suitable. For indoor or less demanding environments, alkyd enamel can generally meet the requirements.

2.Budget

Fluorocarbon paint is a premium product and typically comes at a higher cost, while alkyd enamel is more economically priced. Thus, budget considerations play a role in the decision.

3.Appearance Requirements

Fluorocarbon paint has advantages in appearance and color stability. If maintaining vibrant and non-fading colors over time is crucial, fluorocarbon paint may be the better choice.

In conclusion, both fluorocarbon paint and alkyd enamel have their advantages and specific applications. The choice should be based on the specific requirements of the project. For more precise advice, it is best to consult professional paint suppliers or coating experts.

Fluorocarbon paint and alkyd enamel are fundamentally different types of coatings with significant differences in their compositions and properties. They should not be mixed, as doing so can lead to several issues:

Mixing fluorocarbon paint with alkyd enamel can result in chemical instability due to their different compositions and formulations, potentially leading to chemical reactions that affect the performance and quality of the coating.

Combining these two different types of paints can cause quality problems with the coating, such as poor adhesion, peeling, and color instability.

Mixing different types of paint may result in undesirable visual effects, such as color discrepancies, spots, or uneven finishes.

Mixing paints can generate harmful gases or unsafe chemical reactions, posing potential risks to both workers and the environment.

Therefore, to ensure the performance, quality, and safety of the coating, fluorocarbon paint and alkyd enamel should not be mixed. When selecting and applying coatings, choose the appropriate type based on specific application needs and follow the manufacturer’s guidelines and instructions carefully. For further advice, consult with professional paint suppliers or coating experts to receive accurate recommendations and guidance.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.