Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the title of “Corrosion Protection Master.” However, with a myriad of epoxy primer types available on the market, how do you select the one that best suits your needs? Here are some key factors to help you make an informed decision, accompanied by an illustrative graphic.

The price and performance of epoxy zinc-rich primers largely hinge on the zinc dust content. Zinc dust not only provides cathodic protection but also enhances the coating’s corrosion resistance. However, it’s important to note that a higher zinc dust content is not always better; the choice should be based on coating requirements and substrate preparation. For instance, substrates prepared to Sa2.5 by abrasive blasting may benefit from primers with higher zinc content.

Epoxy resin is the primary film-forming component in epoxy primers, determining the coating’s adhesion, mechanical properties, and corrosion resistance. Epoxy zinc-rich primers with high resin content are more suitable for demanding coating environments, such as offshore platforms and ships.

Epoxy primers are two-component paints, and their curing speed is significantly affected by temperature. In winter, when temperatures are low and curing is slow, winter-type thinners or alternative hardener formulations may be used. Conversely, in summer, with faster solvent evaporation, slow-drying thinners are more appropriate. Therefore, when selecting an epoxy primer, consider seasonal factors to ensure optimal coating performance.

Solid content influences the spread rate, i.e., the area that can be coated per kilogram of paint. Many customers focus solely on the unit price but overlook this aspect. In reality, paints with higher solid content may have a slightly higher price per kilogram but offer a higher spread rate, making them more economical in the long run.

The quality of epoxy primers produced by different manufacturers varies widely. Choosing a reputable and qualified manufacturer ensures that the product has undergone rigorous quality testing and comes with relevant inspection reports and Material Safety Data Sheets (MSDS), safeguarding both coating performance and construction safety.

Epoxy primers come in various types, such as epoxy zinc-rich primer, epoxy iron oxide primer, and epoxy zinc chromate primer, each suited to different coating environments and application areas. For example, epoxy zinc-rich primer is ideal for atmospheric and soil environments, offering excellent salt spray and rust prevention properties, while epoxy iron oxide primer is more suitable for metallurgical, container, and transportation vehicle applications requiring rust prevention.

Epoxy primers often need to be used in conjunction with compatible topcoats to achieve optimal corrosion protection. When selecting an epoxy primer, consider its compatibility and matching with the topcoat to ensure the overall performance of the coating system.

In summary, choosing the right epoxy primer for you involves considering zinc dust content, epoxy resin content, seasonal factors, solid content, manufacturer, coating environment and application areas, as well as topcoat compatibility. Only by making the right choice can you fully leverage the corrosion protection properties of epoxy primers, providing lasting protection for your steel products.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

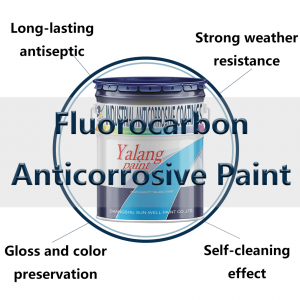

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.