Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

Abstract: During the application of waterproof coatings, workers often fall into certain ingrained bad habits. Due to a lack of awareness or disregard for these habits, the effectiveness of the waterproof coating can be significantly reduced. To improve the quality of waterproofing projects, it’s important to understand the common errors in the application process.

If the substrate is too absorbent and has not been adequately moistened, it will be overly dry. This results in an uneven application of the waterproof coating and can lead to defects such as pinholes, powdering, cracking, and peeling in the dried waterproof layer.

If there is standing water on the substrate surface, applying waterproof coating on such a surface will excessively dilute the liquid material. This affects the coating’s viscosity and coverage, and may prevent the coating from forming a continuous film.

Applying the waterproof coating too thickly in a single coat can slow down the drying process. This often results in a surface that dries faster than the underlying layers, leading to problems like cracking of the thick waterproof layer.

Inconsistent application of the waterproof coating, where some areas are not fully covered, prevents the formation of a complete waterproof layer. This allows moisture to penetrate through uncoated spots, compromising the waterproofing effectiveness.

If protective measures are not taken after applying the waterproof coating, it is prone to contamination and damage during subsequent construction activities. This can lead to the waterproof layer failing and reducing its effectiveness.

The drying time of waterproof coatings can be affected by the construction environment. Performing water-tightness tests before the coating has fully dried can damage the waterproof layer and diminish its effectiveness.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

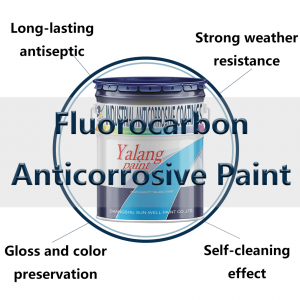

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.