Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

In general, high-temperature paint has many color limitations, unlike other types of paint where any color can be formulated. This is because most pigments cannot maintain their properties at high temperatures, leading to discoloration or blackening. For example:

– Titanium dioxide has excellent thermal stability, retaining its color up to 350–400°C, turning yellow-brown at 600°C, and becoming irreversibly black-brown at 1200–1300°C.

– Red pigment (iron oxide red) is suitable for long-term heat resistance at 250°C.

– Yellow pigments (strontium yellow and cadmium yellow) can only withstand temperatures up to 200°C for extended periods.

– Blue pigment (phthalocyanine blue) is heat-resistant below 200°C.

– Green pigments (Cr₂O₃ and cobalt green)** are suitable for long-term heat resistance at 250°C.

-Aluminum powder has a melting point of about 600°C, commonly used to prepare high-temperature paints that withstand 500–600°C (aluminum color).

– Zinc powder has a melting point of about 420°C, often used to prepare high-temperature paints that withstand 400°C.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

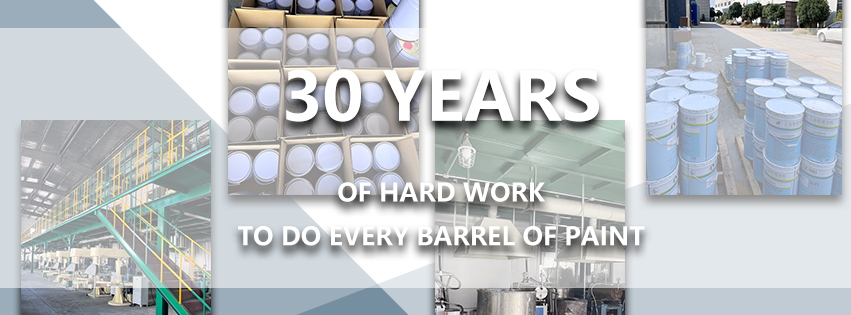

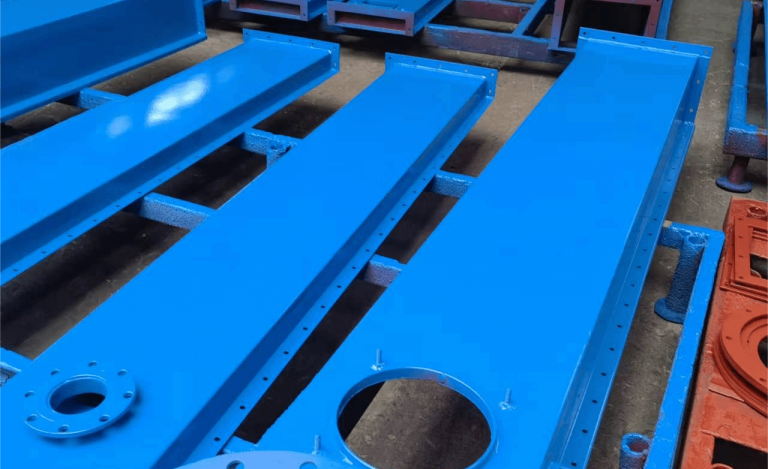

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

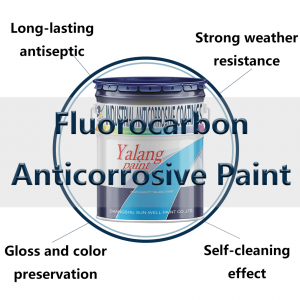

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.