Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

Water-based coatings, as a leading choice among environmentally friendly paints, are gradually becoming a favorite in the field of construction machinery coating. With their outstanding environmental features, they demonstrate strong potential in reducing VOC emissions, signaling that water-based coatings will shine brightly in this field and become a key force in driving the green transformation of the industry. Therefore, we will share some tips for spraying water-based coatings in the painting workshop to help you complete your projects more effectively.

Spraying Sequence: The order of spraying should be from difficult to easy, from inside to outside. Start with higher areas and then move to lower areas, and begin with smaller areas before progressing to larger ones. This approaWater-based coatings, as a leading choice among environmentally friendly paints, are gradually becoming a favorite in the field of construction machinery coating. With their outstanding environmental features, they demonstrate strong potential in reducing VOC emissions, signaling that water-based coatings will shine brightly in this field and become a key force in driving the green transformation of the industry. Therefore, we will share some tips for spraying water-based coatings in the painting workshop to help you complete your projects more effectively.This approach prevents paint mist from splashing onto already coated surfaces, which could damage the finished paint film.

Use clean water to adjust the paint to the appropriate spraying viscosity. Measure with a viscosity cup (e.g., a #4 cup), and the ideal viscosity is generally 20–30 seconds. If you don’t have a viscosity cup, you can use a visual method: Stir the paint with a stick (metal or wood), then lift it to a height of 20 centimeters and observe. If the paint continuously forms a line and does not break for a few seconds, it is too thick. If the line breaks immediately upon lifting, it is too thin. The ideal viscosity is when the paint forms a continuous line at 20 centimeters and then quickly turns into drips.

When spraying outdoors, pay attention to the wind direction (avoid working in strong winds). The operator should stand with the wind to prevent the paint mist from blowing onto the freshly coated surface, which could cause an unsightly speckled appearance.

It is best to control the air pressure between 0.3-0.4 MPa (3-4 kg/cm²). If the pressure is too low, the paint mist will atomize poorly and cause surface pitting. If the pressure is too high, it may lead to runs and excessive mist, which wastes materials and affects the operator’s health.

The spray gun should be moved up and down, left and right, at a uniform speed of 10-12 meters per minute. The nozzle should be kept perpendicular to the surface being coated to minimize angled spraying. When spraying the edges of the surface, quickly release the spray gun trigger to reduce the mist, as the edges often require multiple coats and are prone to runs.

The distance between the nozzle and the surface should generally be 150-250 millimeters. If it is too close, it can lead to runs; if it is too far, the mist may be uneven, leading to pitting and wastage due to dispersion. The specific distance should be adjusted based on the type of paint, its viscosity, and the air pressure. For slow-drying paints, the distance can be a bit farther; for fast-drying paints, it can be closer. Adjust the distance slightly (10-50 millimeters) based on viscosity and pressure to achieve the desired paint film.

Each coat should overlap the previous one by 1/3 or 1/4 to avoid missed spots. When spraying fast-drying paints, complete the spraying in sequence. Touch-ups may not yield ideal results.

No object or process is perfect, and water-based coatings are no exception. While they have their advantages, there are still many issues. However, by continuously improving using the techniques and methods mentioned above, many of these issues can be effectively prevented.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

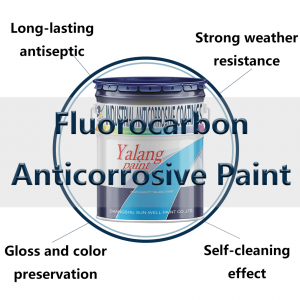

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.