Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

In the process of navigation of the ship, not only the bottom of the ship and contact with water for a long time, but also the external natural environment will bring certain corrosion phenomenon to the ship, and the ship coating can effectively isolate the external water, reduce the corrosion phenomenon to the ship. Water-based anticorrosive coating, as a coating commonly used in ship coating, can be divided into water latex coating and coating that can be diluted in water.

Water latex coating is the resin material as the main manufacturing raw material, based on the principle of emulsion polymerization, it can be made through multiple complex processes. With the continuous development and improvement of related science and technology in China, the emulsion polymerization technology is in a steady state of development, and has a good market development prospect. The emulsion polymerization technology integrates two forms of homogeneous emulsion polymerization and heterogeneous emulsion polymerization, which also belongs to the core and shell structure in essence. Emulsion polymerization can be used for the improvement of resin preparation technology. Through the polymerization modification of emulsion, the performance of water emulsion coating is significantly improved. At present, the modified resin used in the production of water latex coating is based on epoxy resin, alkyd resin and other materials.

The coating that can be diluted in the water needs to be dissolved in the resin solvent, so that it can be fully mixed with other materials, and it needs to use the water-soluble solvent to ensure that the salt group is gradually dissolved in the water, and then painted on the ship. In this coating of resin material application types has obvious limitation, with the current polyurethane resin and epoxy resin, mainly because of the resin material chain molecules exist more number of hydrophilic molecular group, after processing polymer can fully fusion with water, because this coating can fully dissolved in water, usually used in electrophoretic primer, only in part of very special cases, will be used for gas dry coating equipment coating function. This kind of water-based anticorrosive coating, which can be diluted in water, can be prepared based on the core and shell structure, and the pH value of the coating is low. In the process of relevant personnel in the production and preparation of this kind of coating, the need to meet the material requirements of the resin application acid value radical as the basis, to ensure the full docking of the medium and the target molecular chain, to ensure that the final formation of coating polymer can have a good dispersion ability in water.

With the current development of transportation industry, the tonnage of ships used in Marine transportation industry is constantly increasing. In the process of ship operation, the attachment of Marine life in the bottom of the ship is very common, and it brings huge economic losses to the shipping industry every year. Low surface anti-fouling coating can effectively solve the phenomenon of ship corrosion caused by Marine biological attachment. With the modern society paying great attention to the coordination of economic development and ecological environment protection, the toxicity of low surface energy antifouling paint is also declining, which can effectively protect the fragile Marine environment. Marine low surface energy antifouling coatings are mainly organic for organic fluorine and silicone series of protective coatings. After years of development, with the joint efforts of relevant experts and scholars, some research results have been achieved to avoid the corrosion phenomenon caused by Marine life attached to the ship and reduce the economic losses. The low surface antifouling coating of organic fluorine series, in the research and development of difficulty than silicone protective coating, which also means that the low surface antifouling coating of organic fluorine has not really completed the industrial transformation.

With the rapid development of the shipbuilding industry in the world, the ship coating and coating industry also has a relatively broad market development space, representing the titanium dioxide used for the Marine coating also has a broad market development prospect, and the demand for materials maintains an increasing trend year by year. But in order to ensure that the ship coating coating, can play its anti-corrosion role at the same time, to avoid damage to the ecological environment, for rutile titanium dioxide special field requirements have become more and more strict. Western developed countries for titanium dioxide research, and technical monopoly for developing countries, many developing countries, including China, for ship coatings in the process of special rutile titanium dioxide is still in the research stage, our country is for the field into more human resources, has obtained the corresponding development achievements.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

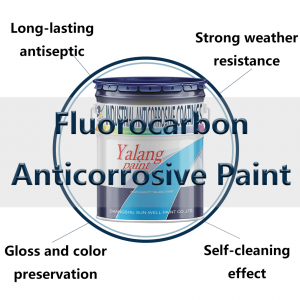

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.