Corrosion Protection Master: How to Choose the Right Epoxy Primer for You?

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

Before coating the steel structure, in order to bond the coating to the substrate, the coated steel surface and the nearby area must be pre-treated.

First, the surface must be clean, without dust, oil, water stains or other dirt and loose oxides.

Secondly, when spraying, the combination of the coating and the substrate is generally mainly mechanical combination. Therefore, on the premise of not affecting the spraying quality, the coating and the substrate should increase the contact area as much as possible, and the appropriate roughness can help improve the adhesion of the coating film and extend the life of the coating.

Related data introduction: Alkyl acid coating is used for manual surface rust removal, the service life of its coating is 2~3a, and the service life of sandblasting treatment reaches Sa 2.5 class can be 10a.

The quality of steel surface pretreatment directly affects the apparent quality of coating engineering and the service life of coating, while the cleanliness and roughness of steel structure surface treatment directly affect the service life of coating.

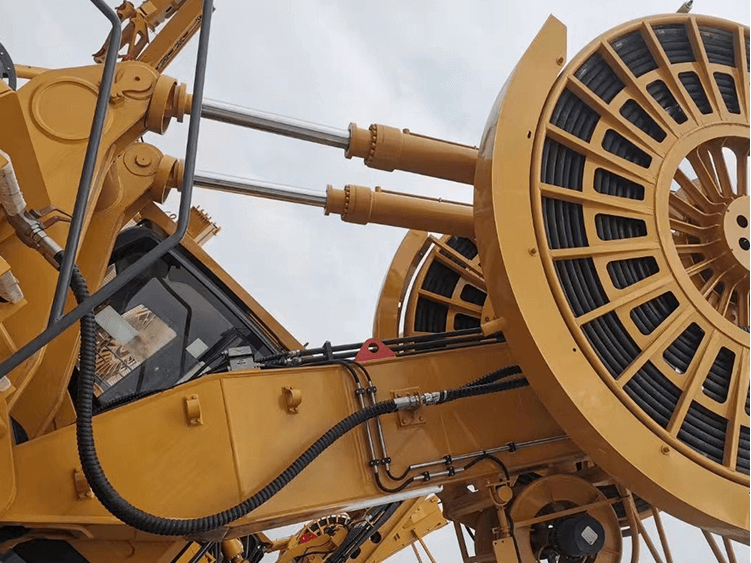

In order to increase the contact area of the coating and the matrix as much as possible, the mechanical thickening and sandblasting coarsening methods are generally adopted. Mechanical coarsening includes shot blasting treatment, manual grinding and polishing treatment. Sand blasting coarse is a diameter of 1~2mm dry and angular yellow sand or quartz sand, using compressed air sand from sandblasting gun nozzle to the steel surface, using sand impact and friction, the surface of steel oxide, rust, paint film, grease and other dirt removal, and obtain a certain roughness surface process. Generally speaking, the higher the steel grade, the higher the surface treatment requirements.

The surface area of the blasted steel structure is about 90 times that of the blasted steel, which greatly increases the contact area between the coating and the substrate. This has a great impact on the adhesion of some coating films, especially the inorganic zinc-rich coatings

In order to meet the requirements of the process and design, and take into account the inheritance and continuity of the process, through the test, we decided to adopt the surface treatment and coating process combining sandblasting and precoated primer.

Note: The above content is compiled from online sources. If there are any copyright infringements, please contact us for removal!

As the source manufacturer, Jiangsu Zhongke Sunwell Technology Co, Ltd. have spent 30 years doing a good job in every barrel of paint, and providing industry supporting solutions for free.

Have questions?Reach out to us, and we will provide you with a perfect solution.

In the realm of corrosion protection, epoxy primers are renowned for their robust anti-corrosion and rust-prevention properties, earning them the

As a member of the epoxy paint family, it is one of the most familiar epoxy products, which is widely

Look closely at the three major types of fluorocarbon coating on the market! Fluorocarbon paint generally refers to fluorocarbon paint,

2024 © YaLang All Rights Reserved

Download our catalog to check all of our products and data sheet, select the right coatings for your projects.