Chlorinated rubber topcoat

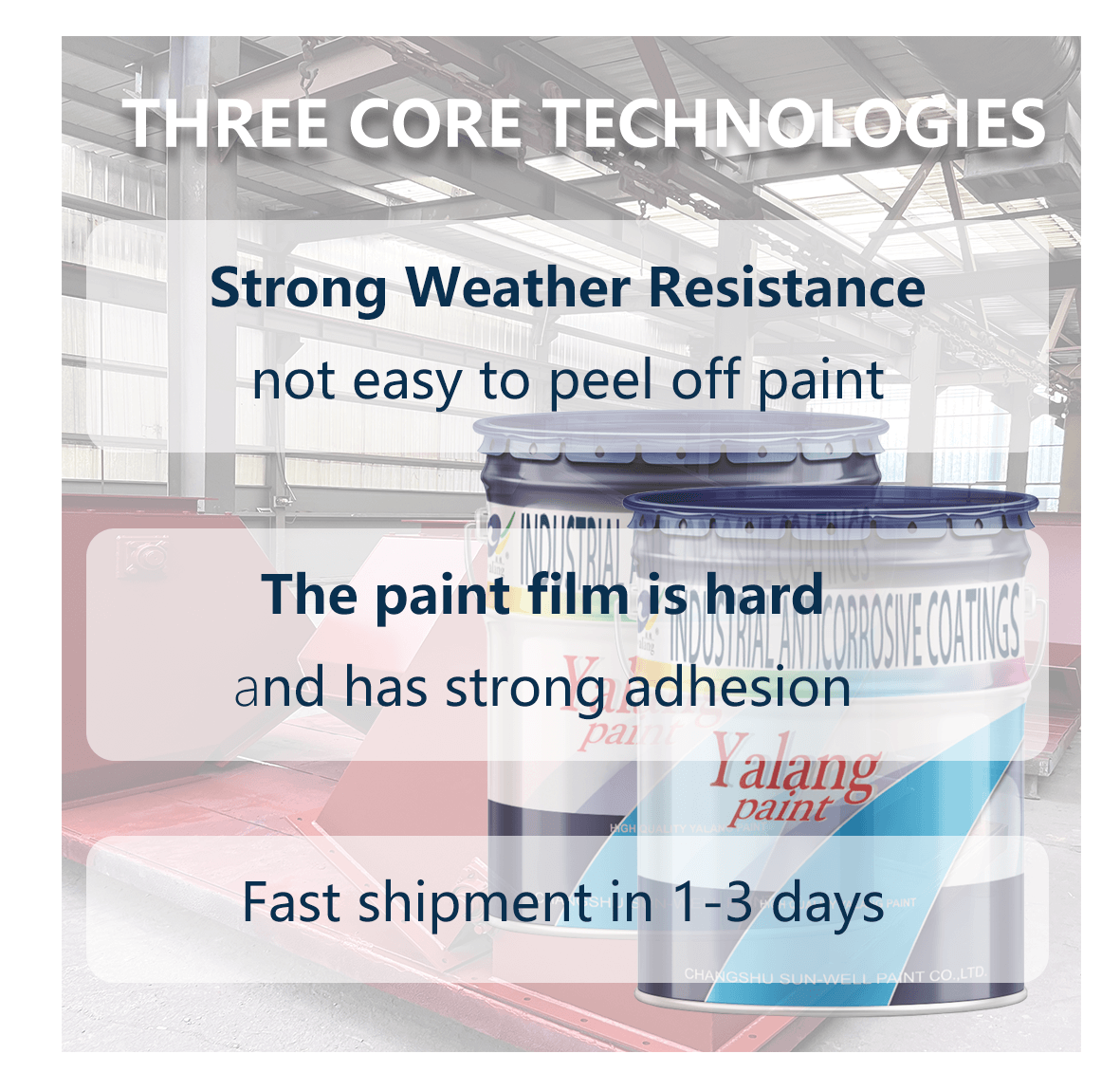

The coating is a volatile coating, the paint film dries quickly, has good anti-corrosion performance, can be applied at a lower temperature, and has good resistance to moisture, acid and alkali, chemical gas and flame retardant properties and salt spray resistance.

CHLORINATED RUBBER TOPCOAT

PRODUCT PARAMETERS

| Coating appearance | Chlorinated rubber topcoat | ||

| Color | A variety of national standard colors | ||

| Drying time | Surface dry≤30min (23°C) Dry ≤6 h (23°C) | ||

| Adhesion | Level ≤1 (Grid) | ||

| The recommended number of coatings | 2 channels, dry film 70 μm | ||

| Density | Approx. 1.3g/cm³ | ||

| Overcoat interval | |||

| Substrate temperature | 0℃ | 25℃ | 40℃ |

| Long time | 6h | 4h | 2h |

| Short time | Unlimited | ||

| Remark | When applying the post-coating, the surface of the front-end paint film should be dry without any contamination | ||

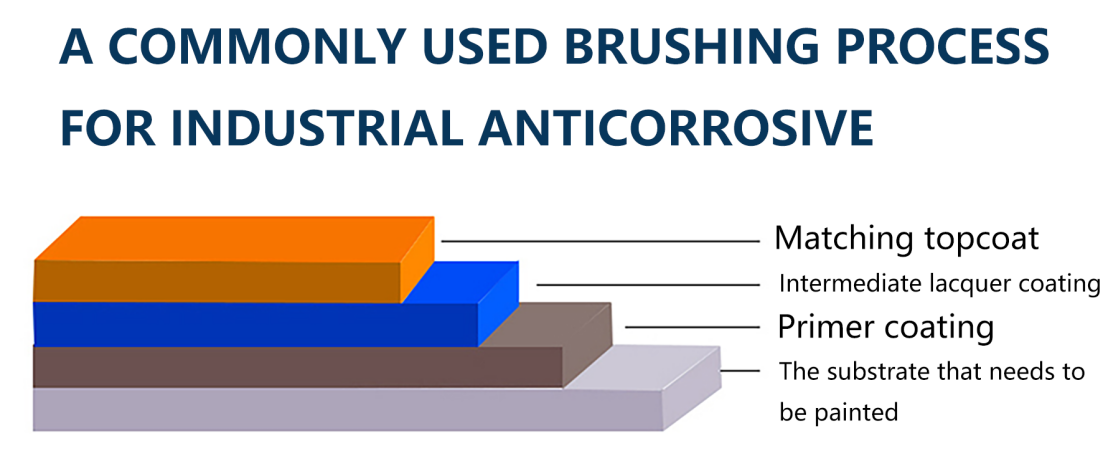

Back-end matching: chlorinated rubber primer, epoxy, polyurethane anticorrosive coating.

1. The substrate must be clean and dry without any contaminants

2. Unpainted surface: sandblasted to Sa2.5 level, surface roughness 30~70μm

3. Pre-coated zinc surface: clean, dry, contaminant, zinc-free.

4. The old paint film that can be matched: remove all pollutants, clean and dry.

PRODUCT DESCRIPTION

Chlorinated rubber topcoat is a coating with chlorinated rubber as the base material, coloring pigments, plasticizers and other additives. It dries quickly, can be painted at low temperature, has strong film adhesion, durability, anti-corrosion, and good waterproof performance. The paint film layer is miscible with each other, and has excellent interlayer adhesion.

Construction conditions: The substrate temperature is higher than 3°C to prevent condensation.

Mix: Stir the paint well.

Dilution: You can add an appropriate amount of supporting diluent, stir evenly and adjust to the construction viscosity.

The construction site should have a good ventilation environment to prevent the inhalation of solvent gases and paint mist. The product should be kept away from the heat source, and smoking is strictly prohibited on the construction site.

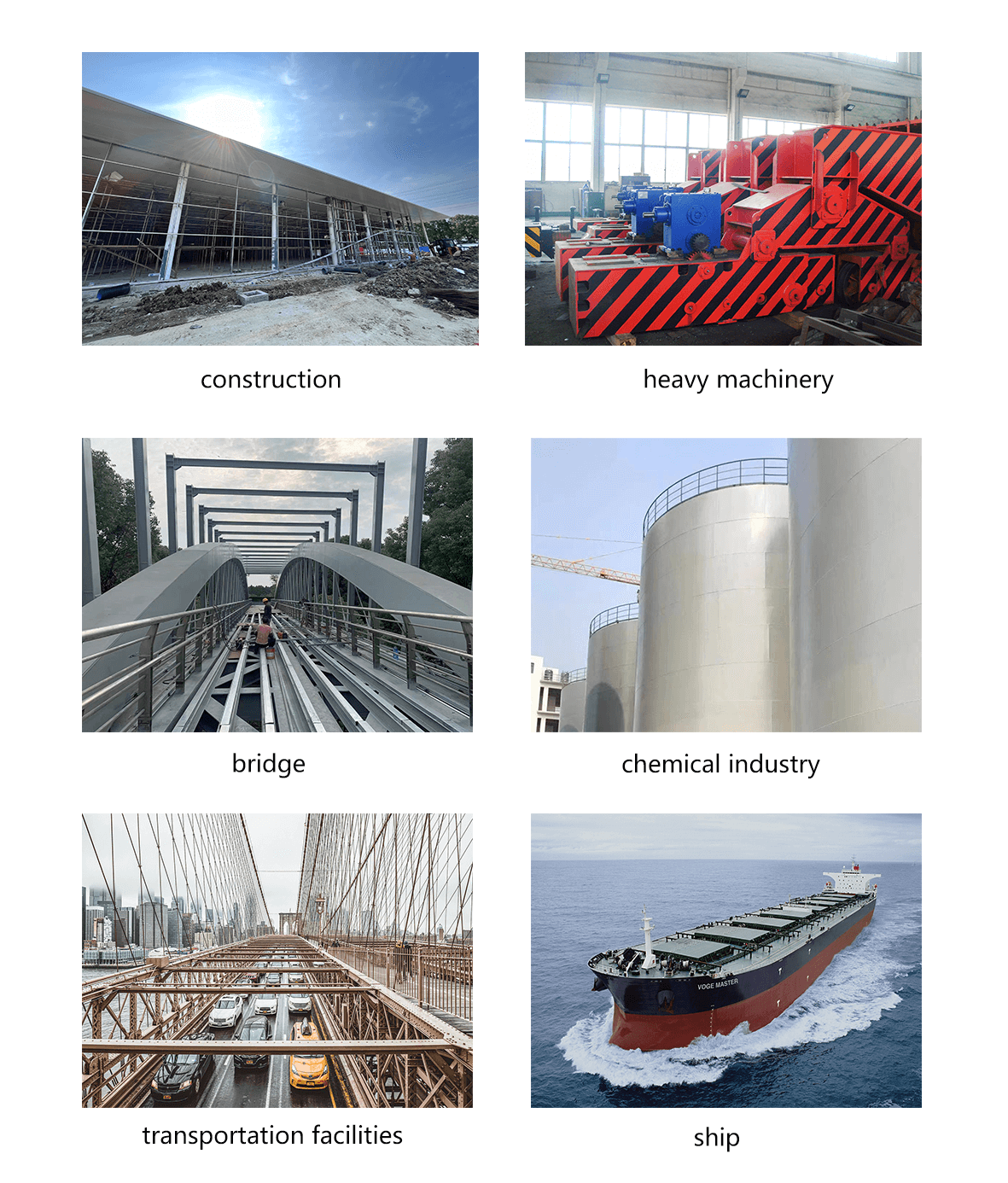

SCOPE OF APPLICATION

It is suitable for anti-rust primer on the surface of steel exposed to general atmospheric environment, chemical atmospheric environment, and marine atmospheric environment.