Epoxy anticorrosive topcoat

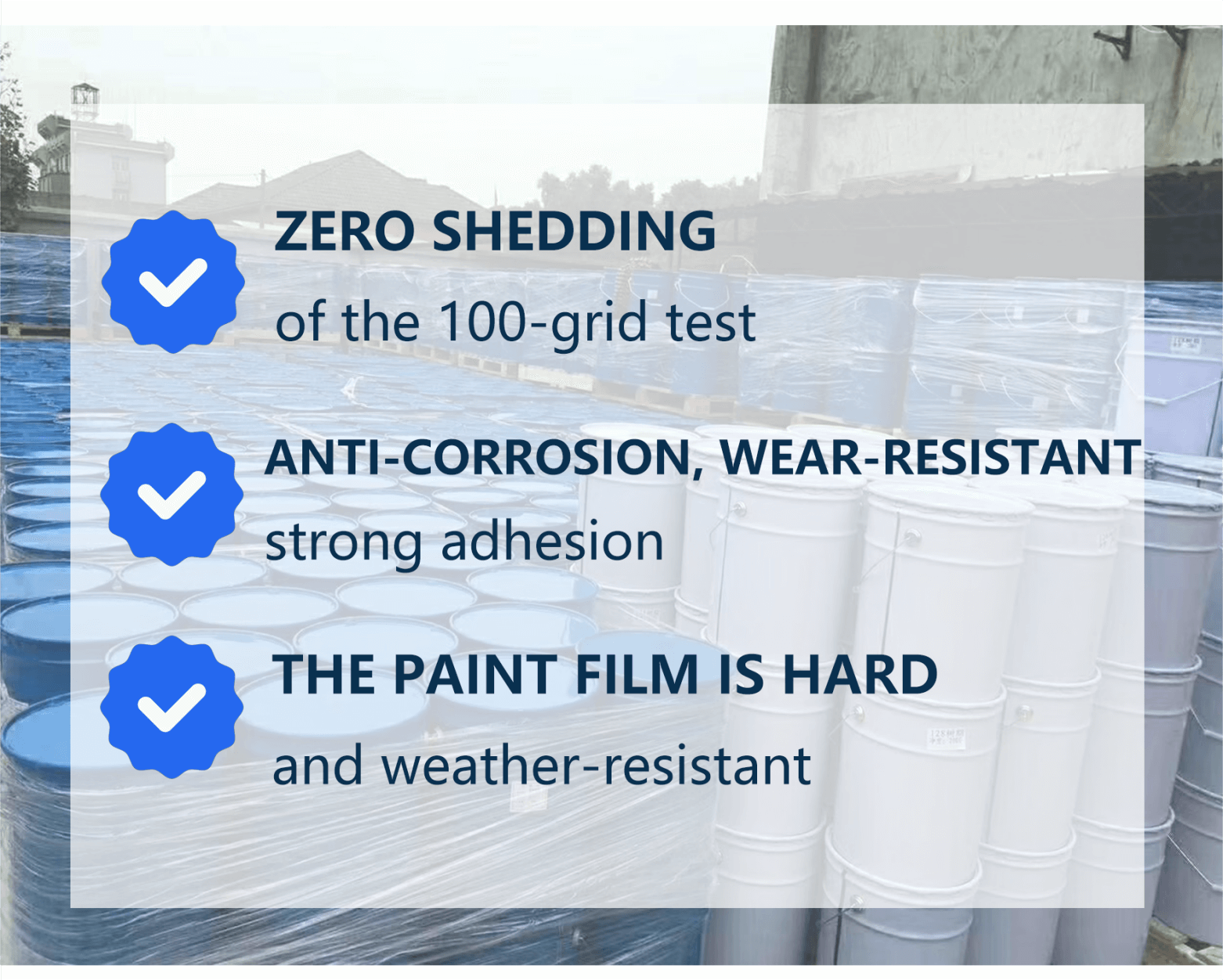

Product features:

Epoxy anticorrosive topcoat is a two-component coating composed of epoxy resin, titanium dioxide and other coloring pigments, epoxy curing agents, additives, etc.

It has a high solids content and forms a dense and hard coating that can be made into a thick-film topcoat. It has good salt water resistance, oil resistance, and chemical resistance. The weather resistance is slightly poor, and after a long period of exposure, the surface will be slightly chalked, which will affect the appearance but have little impact on the protective performance.

Uses:

Used as epoxy zinc-rich, inorganic zinc-rich primer and epoxy intermediate paint, as a supporting topcoat for paint with high anti-corrosion performance, and used as a place with high anti-corrosion requirements such as ships, mining machinery, and offshore facilities.

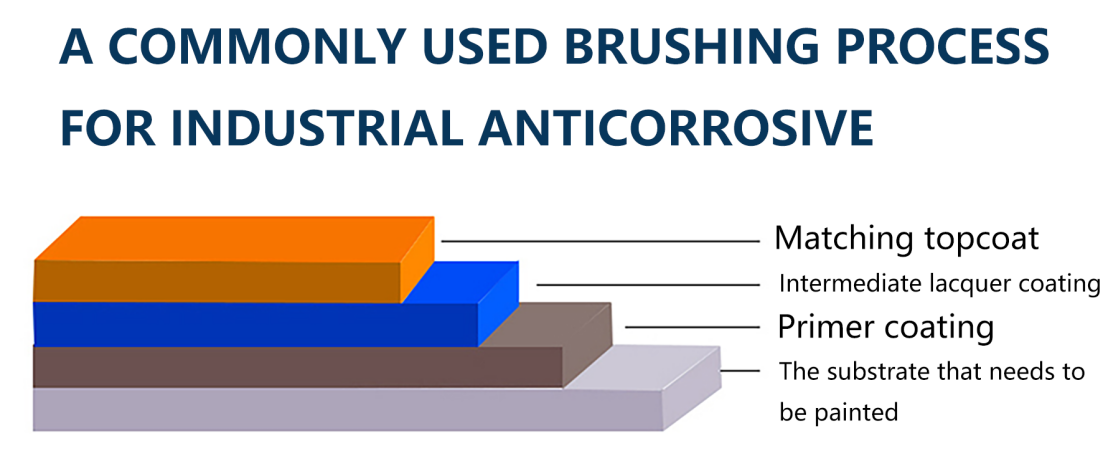

Matching:

Front matching: epoxy zinc-rich primer, inorganic zinc-rich primer, epoxy intermediate paint, etc.

EPOXY ANTICORROSIVE TOPCOAT

TECHNICAL PARAMETERS

| Coating appearance | The coating film is flat and smooth | ||

| Color | A variety of national standard colors | ||

| Drying time | Surface dry ≤ 5h (23 °C) Solid ≤24 h (23 °C) | ||

| Fully cured | 7d(23 °C) | ||

| Ratio | 5:1(Weight Ratio) | ||

| Maturation time | 20min | ||

| Adhesion | Level ≤1 (Grid) | ||

| The recommended number of coatings |

1~2 channels, dry film thickness 100 μm | ||

| Density | Approx. 1.4g/cm³ | ||

| OVERCOAT INTERVAL | |||

| Substrate temperature | 5℃ | 25℃ | 40℃ |

| Long time | 36h | 24h | 16h |

| Short time | No limit (no zinc salts formed on the surface) | ||

| Remark | There is no chalking and other pollutants on the surface during overcoating, there is generally norestriction on long coating, and it is beneficial to obtain good interlayer adhesion before thefront coating film is completely cured, otherwise attention should be paid to the cleanliness ofthe surface of the front coating, and if necessary, it should be brushed to obtain good interlayer adhesion. | ||

Front matching: epoxy zinc-rich primer, inorganic zinc-rich primer, epoxy intermediate paint, etc. Before construction, the surface of the substrate must be clean and dry without any pollution; The substrate is sandblasted to Sa2.5 grade, and the surface roughness is 40-75um.

PRODUCT DESCRIPTION

Epoxy anticorrosive topcoat is a two-component coating composed of epoxy resin, titanium dioxide and other coloring pigments, epoxy curing agents, additives, etc. It has a high solids content and forms a dense and hard coating that can be made into a thick-film topcoat. It has good salt water resistance, oil resistance and chemical resistance. The weather resistance is slightly poor, and after a long period of exposure, the surface will be slightly chalked, which will affect the appearance but have little impact on the protective performance.

Construction conditions: the temperature of the substrate must be higher than 3 °C, the temperature of the substrate during outdoor construction, when it is lower than 5 °C, the curing reaction of epoxy resin and curing agent stops, and it is not suitable for construction. Mixing: Component A should be stirred evenly first, and then component B (curing agent) should be added to mix, stir evenly thoroughly, and it is recommended to use a power stirrer. Dilution: After the mixture is evenly mixed and fully matured, an appropriate amount of supporting diluent can be added, stirred evenly, and adjusted to the construction viscosity before use.

The construction site should have a good ventilation environment to prevent the inhalation of solvent gases and paint mist. The product should be kept away from the heat source, and smoking is strictly prohibited on the construction site.

Eyes: If paint splashes into your eyes, rinse immediately with plenty of water and seek medical attention.

Skin: If the skin is stained with paint, rinse with soap and water or use an appropriate industrial cleaner, do not use large amounts of solvents or thinners.

Inhalation or inhalation: due to inhalation of a large amount of solvent gas or paint mist, it should be immediately moved to a fresh place of air, loosen the collar, and let it gradually recover. f ingested with paint, seek medical attention immediately.

Storage: It must be stored in accordance with national regulations, the environment is dry, ventilated and cool, avoid high temperature and keep away from fire.

Storage validity: 12 months, after which it should be used after passing the inspection

Packing: 20kg for part A and 5kg for part B

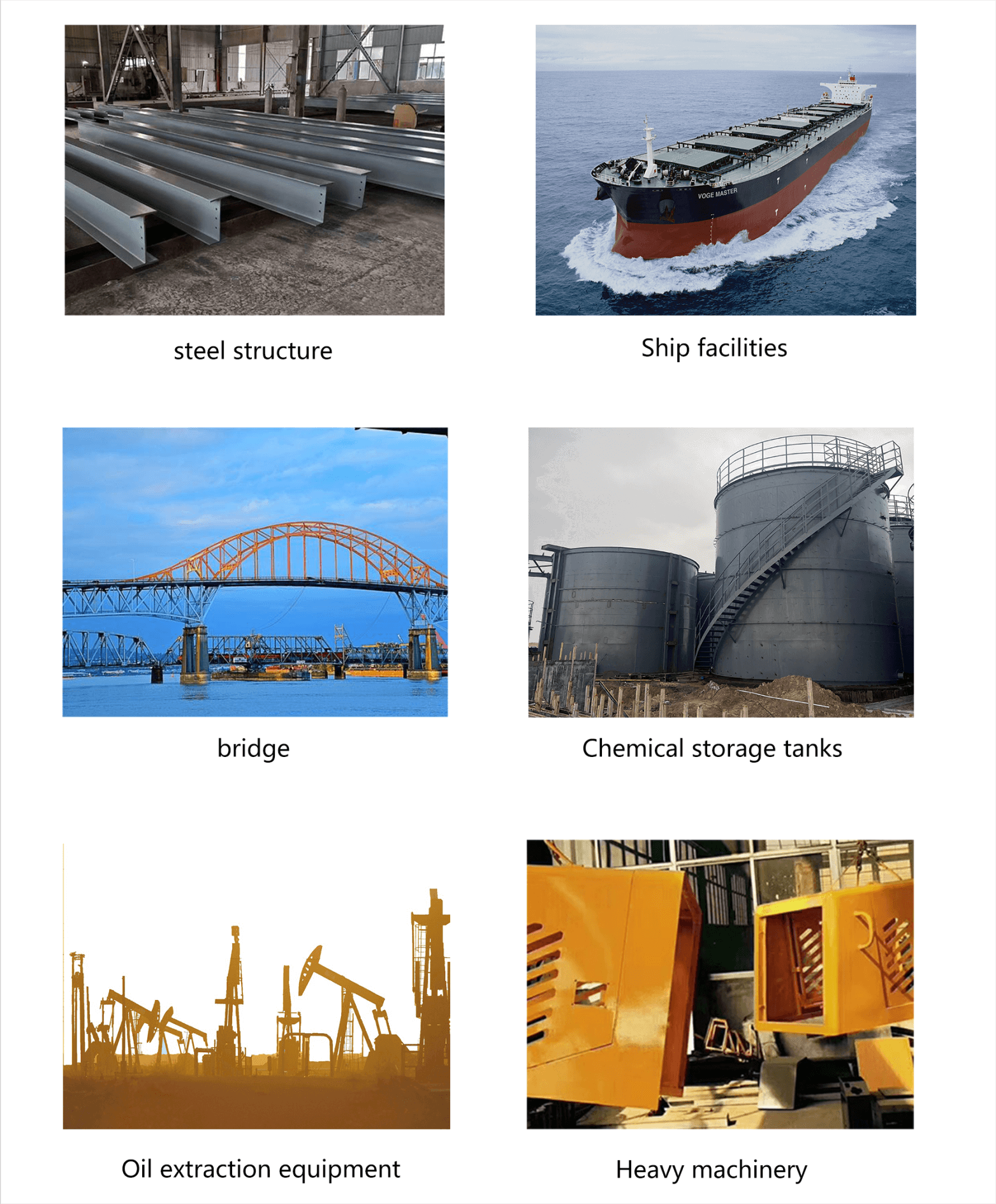

SCOPE OF APPLICATION

It is used as epoxy zinc-rich, inorganic zinc-rich primer and epoxy intermediate paint, as a supporting topcoat for paint with high anti-corrosion performance, and is used as a place with high anti-corrosion requirements such as ships, mining machinery, and offshore facilities.