Epoxy zinc-rich primer

Features:

The two-component coating composed of epoxy resin, ultra-fine zinc powder, modified curing agent and additives, etc., has high content of zinc powder and excellent anti-corrosion performance.

It has good cathodic protection.

It has good salt spray resistance and damp heat resistance.

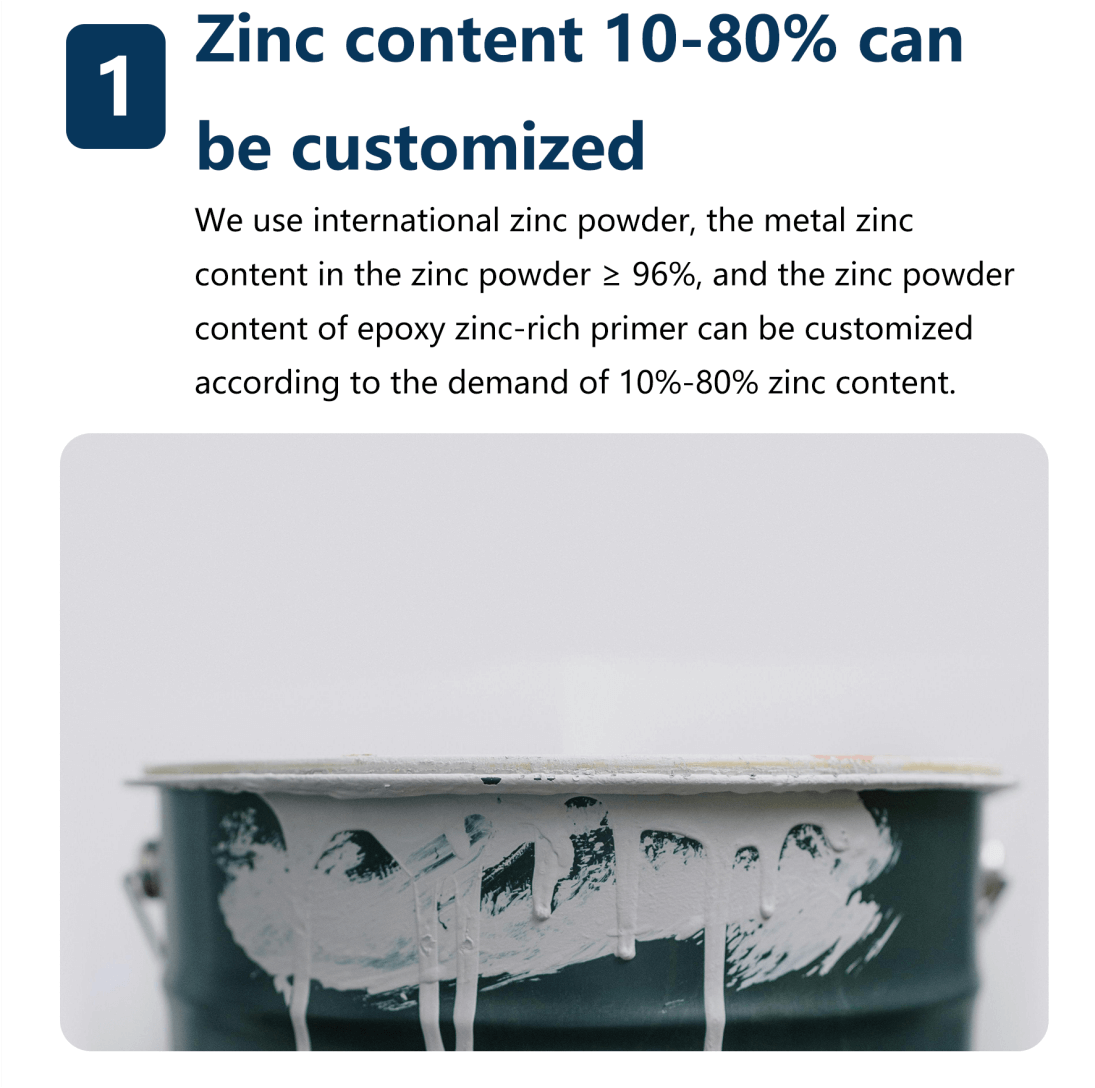

The coating film is hard, impact resistant, and has good adhesion.

It has good oil and solvent resistance.

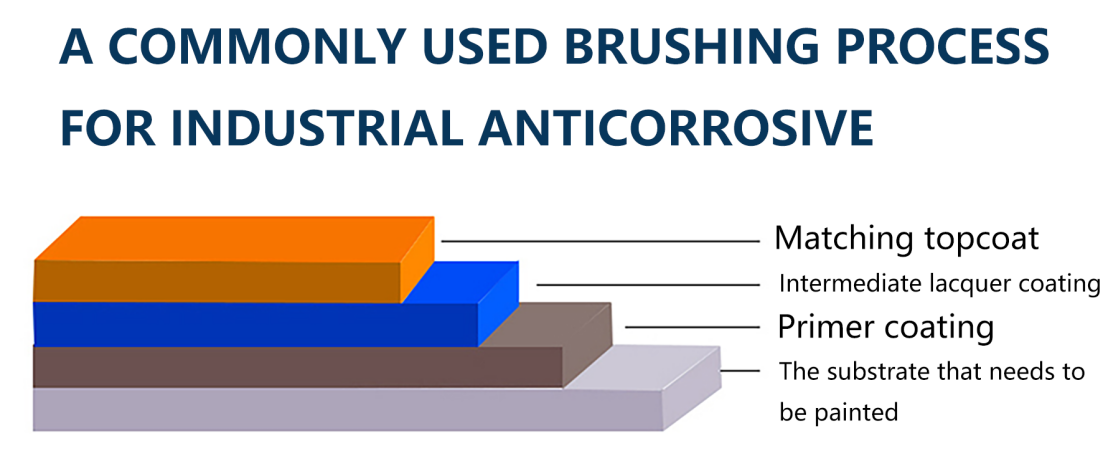

It can be used with most high-performance anti-rust paints and topcoats.

EPOXY ZINC-RICH PRIMER

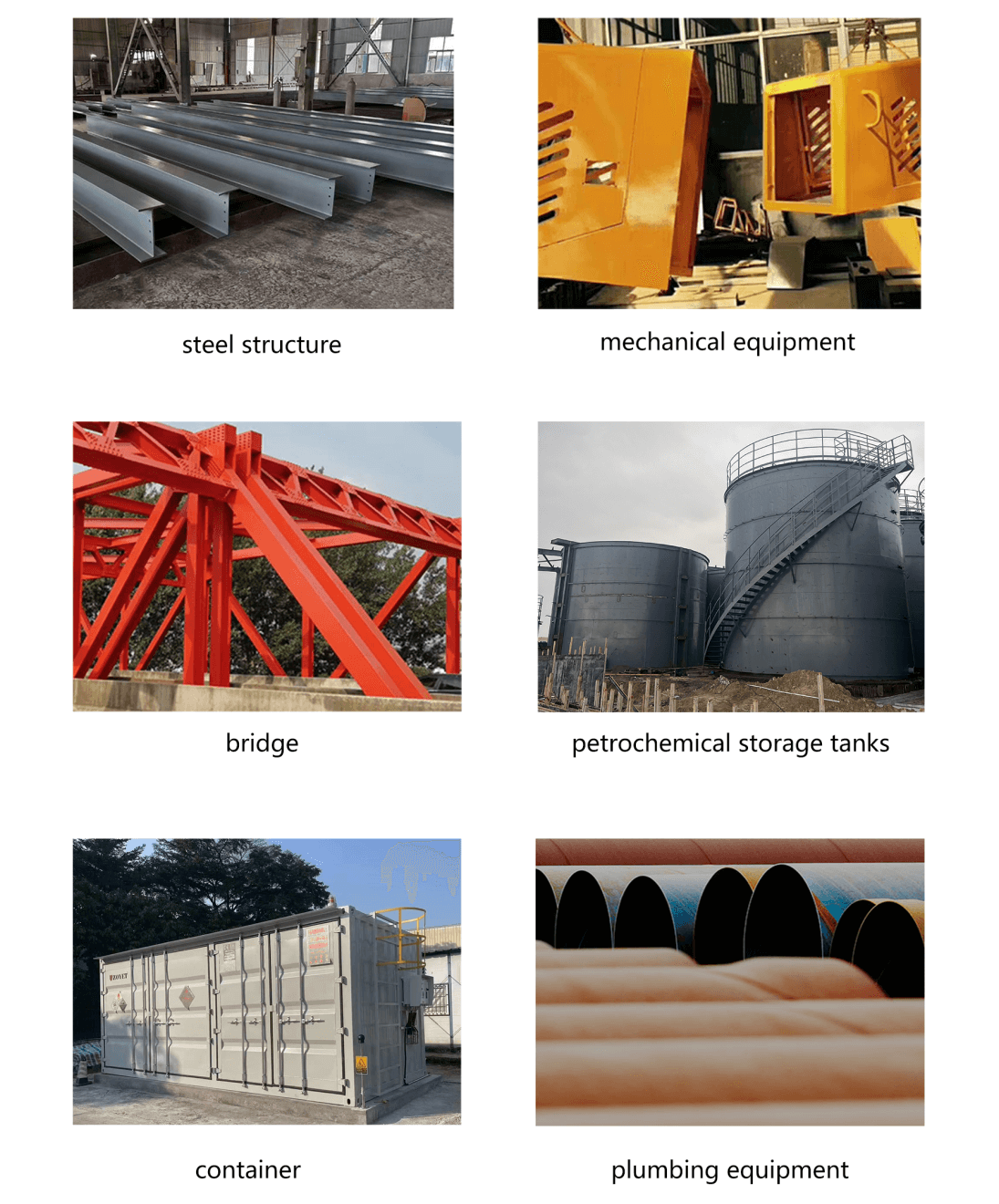

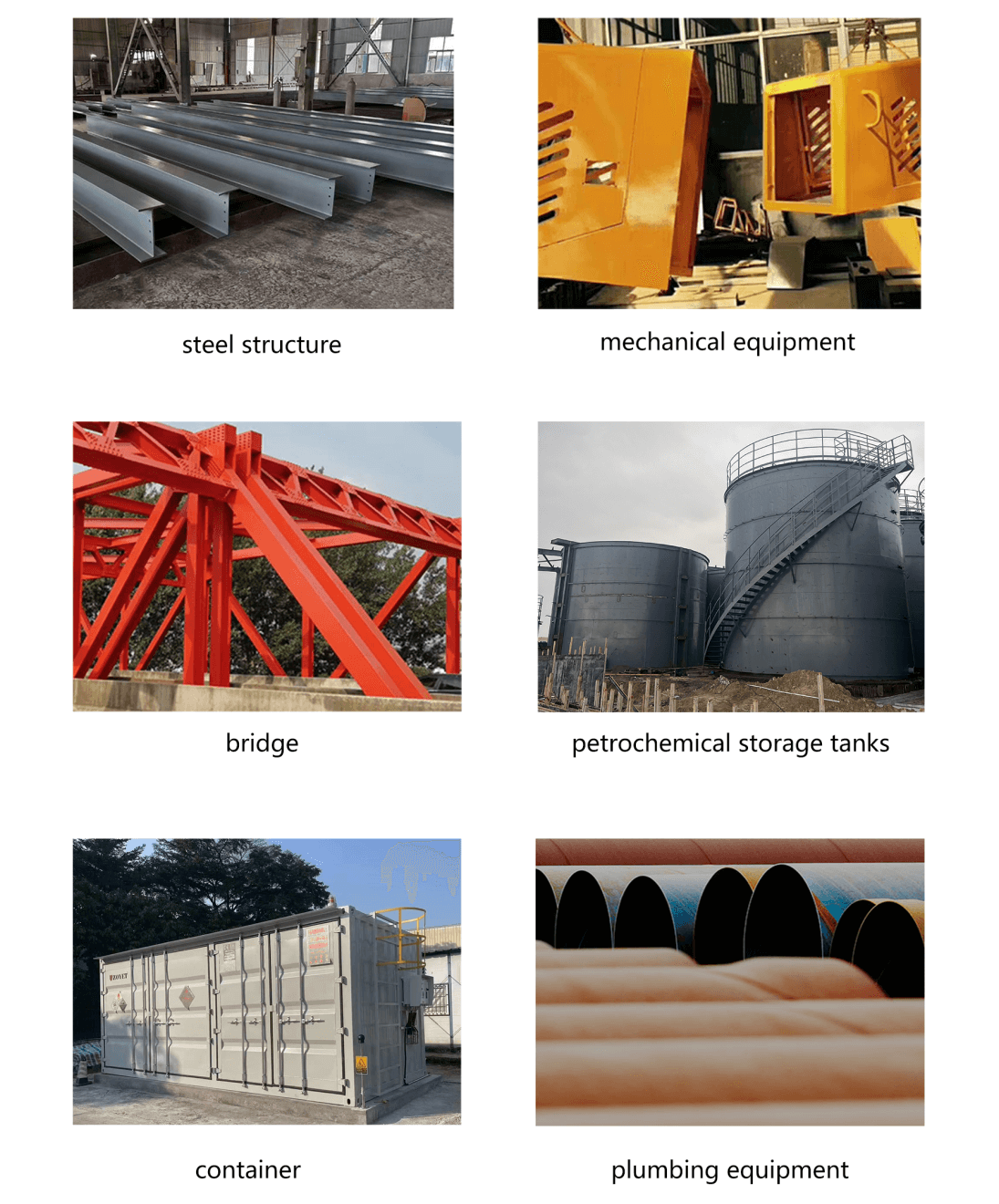

SCOPE OF APPLICATION

It is widely used in anti-rust and anti-corrosion of metal substrates such as containers, petrochemical industries, steel structures, bridges, pipelines, tank pipes, heavy machinery and equipment, etc.

PRODUCT INFORMATION

Epoxy zinc-rich primer is a two-component coating composed of epoxy resin, ultra-fine zinc powder, modified curing agent and additives, etc., with high content of zinc powder and excellent anti-corrosion performance. It has good cathodic protection, good salt spray resistance and damp heat resistance, hard coating film, impact resistance, good adhesion, good oil resistance and solvent resistance, and can be used with most high-performance anti-rust paints and topcoats.

| Coating appearance | The coating film is smooth and matte | ||

| Color | Grey | ||

| Drying time | Surface dry ≤ 45min (23 °C) Solid ≤24 h (23 °C) | ||

| Fully cured | 7d | ||

| Maturation time | 20min (23 °C) | ||

| Ratio | 10:1(Weight Ratio) | ||

| Adhesion | Level ≤1 (Grid) | ||

| The recommended number of coatings |

Airless spraying is applied in one piece, and the dry film is 50-80 μm |

||

| Density | Approx. 2.3g/cm³ | ||

| OVER INTERVAL | |||

| Substrate temperature | 5℃ | 25℃ | 40℃ |

| Long time | 48h | 24h | 8h |

| Short time | No limit (no zinc salts formed on the surface) | ||

| Remark | When the post-coat is applied, the paint film should be dry, and the front paint film should not be polluted | ||

Rear supporting: zinc-rich primer, epoxy primer, epoxy intermediate coat, etc. The surface must be dry and clean before construction, free of any contaminants (grease, zinc salts, etc.)

Construction conditions: The temperature of the substrate must be higher than 3°C to prevent condensation, and the relative humidity should not be greater than 80% when working outdoors.

Mixing: Component A should be stirred evenly first, and then component B (curing agent) should be added to mix, and stirred thoroughly.

Dilution: Components A and B are mixed evenly, and after fully curing, an appropriate amount of supporting diluent can be added, stirred evenly, and adjusted to the construction viscosity.

The construction site should have a good ventilation environment to prevent the inhalation of solvent gases and paint mist. The product should be

kept away from the heat source, and smoking is strictly prohibited on the construction site.

Eyes: If paint splashes into your eyes, rinse immediately with plenty of water and seek medical attention.

Skin: If the skin is stained with paint, rinse with soap and water or use an appropriate industrial cleaner, do not use large amounts of solvents or thinners.

Inhalation or inhalation: due to inhalation of a large amount of solvent gas or paint mist, it should be immediately moved to a fresh place of air, loosen the collar, and let it gradually recover. f ingested with paint, seek medical attention immediately.

Storage: It must be stored in accordance with national regulations, the environment is dry, ventilated and cool, and high temperature and far away from the fire source.

Storage validity: 12 months, after which it should be used after passing the inspection

Packing: Part A: 25kg, Part B: 3.2kg