Alkyd antirust paint

Alkyd antirust paint is composed of alkyd resin as the base material, adding antirust pigments, additives and solvents. It has good adhesion. Anti-rust properties. Fast drying, good adhesion and easy construction.

ALKYD ANTIRUST PAINT

PRODUCT PARAMETERS

| Coating appearance | The coating film is smooth and bright | ||

| Color | Iron red, gray | ||

| Drying time | Surface dry ≤ 4h (23 °C) Solid ≤24 h (23 °C) | ||

| Adhesion | Level ≤1 (Grid) | ||

| Density | Approx. 1.2g/cm³ | ||

| Overcoat interval | |||

| Substrate temperature | 5℃ | 25℃ | 40℃ |

| Short time | 36h | 24h | 16h |

| Long time | No limit | ||

| Remark | When the post-coat is applied, the paint film should be dry, and the front paint film should not be polluted | ||

Rear matching: alkyd paint.

Before construction, the surface must be clean, dry and free of any pollution; When the anti-corrosion level is high, the anti-rust grade of the coated surface reaches St3 or Sa2.5

PRODUCT DESCRIPTION

Alkyd antirust paint is composed of alkyd resin as the base material, adding antirust pigments, additives and solvents. It has good adhesion. Anti-rust properties. Fast drying, good adhesion and easy construction.

Construction conditions: The substrate temperature is higher than 3°C to prevent condensation.

Mix: Stir the paint well.

Dilution: You can add an appropriate amount of supporting diluent, stir evenly and adjust to the construction viscosity.

The construction site should have a good ventilation environment to prevent the inhalation of solvent gases and paint mist. The product should be kept away from the heat source, and smoking is strictly prohibited on the construction site.

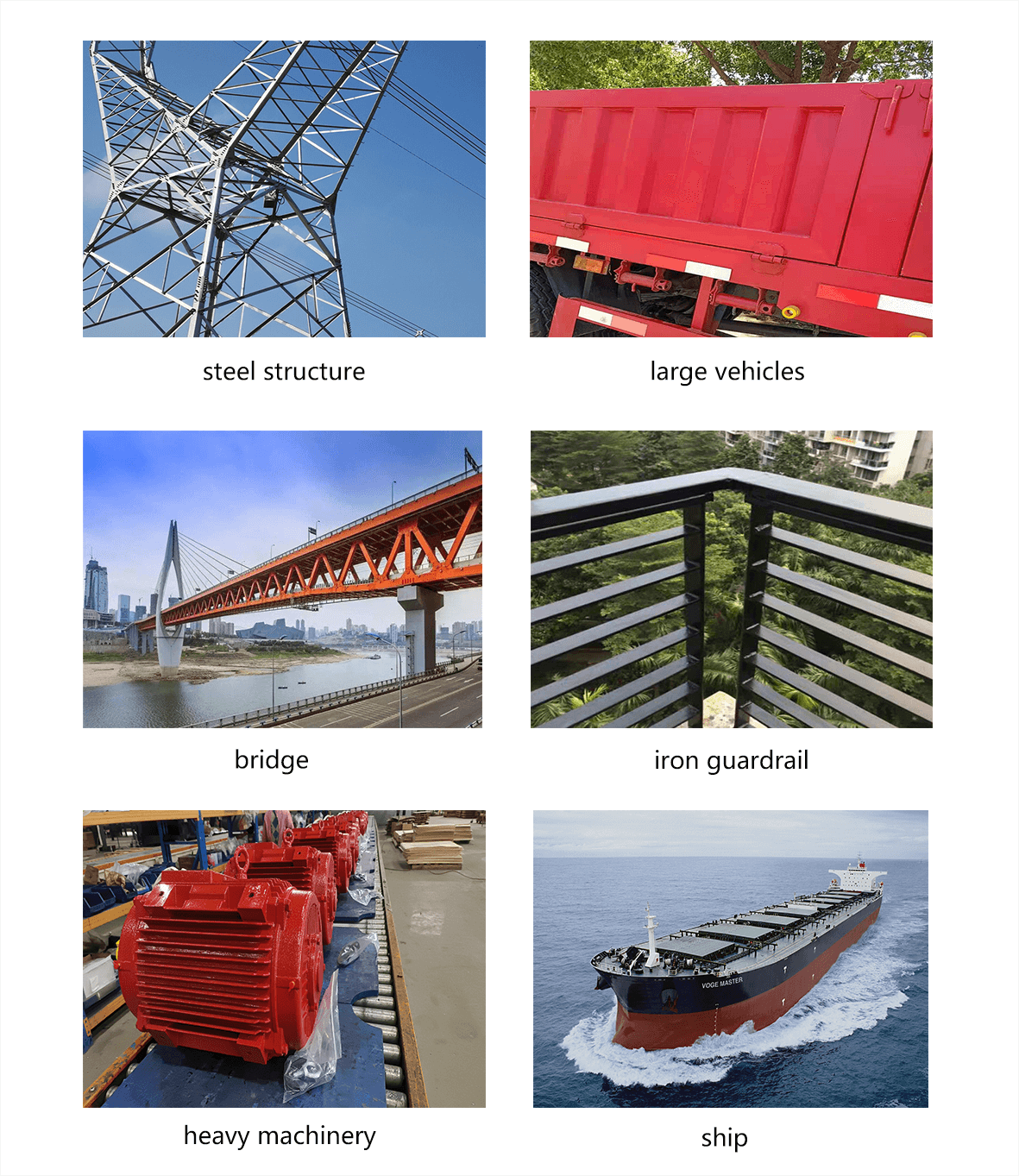

SCOPE OF APPLICATION

It is used for anti-rust coating of machinery and equipment and steel structures.